Insights

November 27, 2024

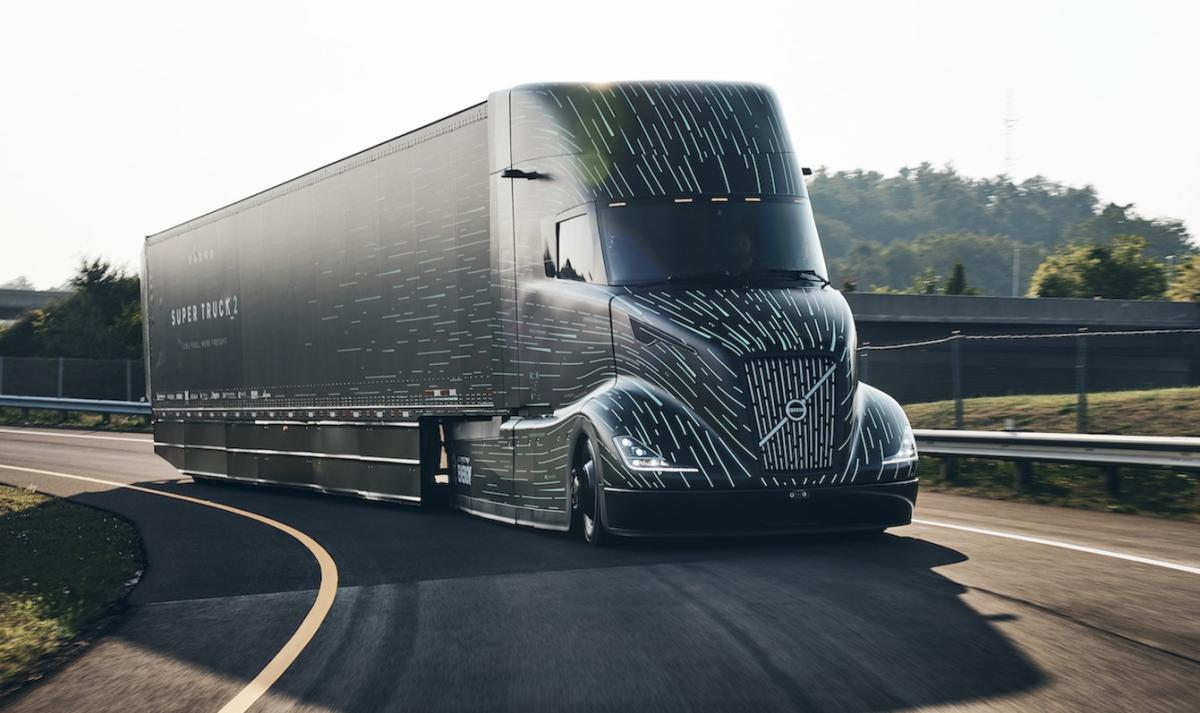

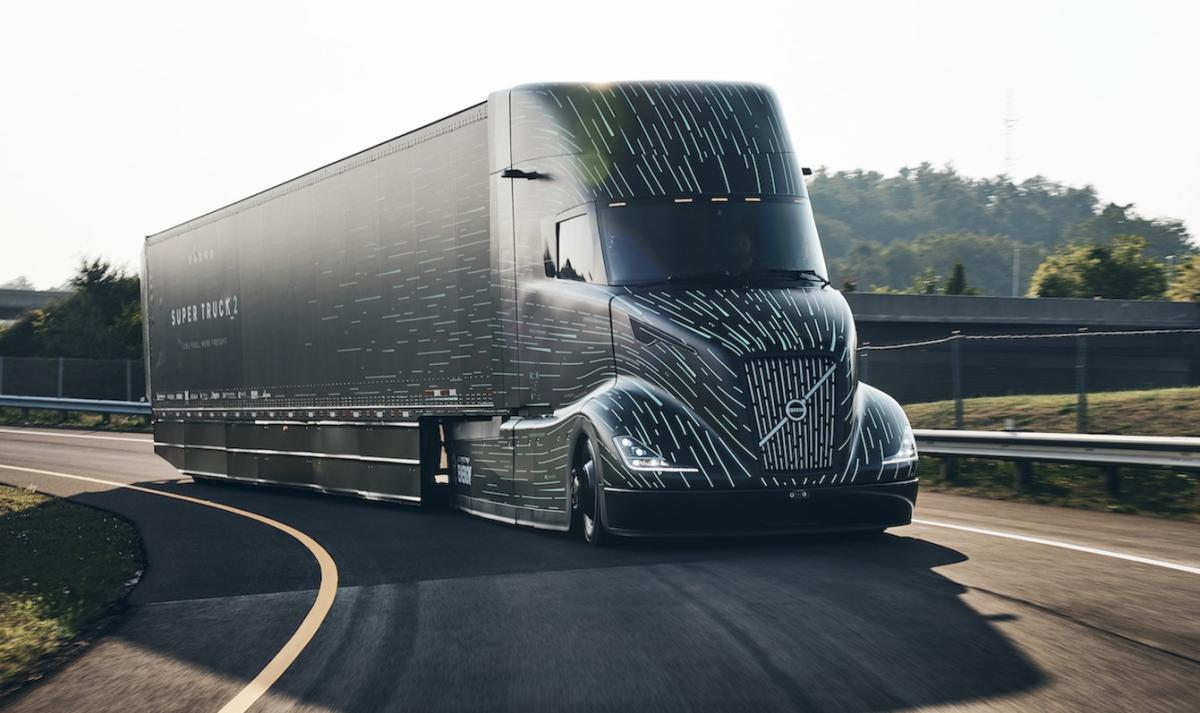

As Diesel Prices Remain High, US Trucking Companies are Investing in Fuel-Saving Technologies

Insights

November 27, 2024

As Diesel Prices Remain High, US Trucking Companies are Investing in Fuel-Saving Technologies

With diesel prices pushing profitability into tight margins, trucking companies in the US are leveraging cutting-edge fuel-saving technologies like aerodynamics and hybrid powertrains. Discover how these advancements are transforming the future of freight transportation.

Diesel is the lifeblood of the trucking industry, propelling millions of trucks each year across the highways that power the US supply chain. Yet for decades, the industry has ridden the rollercoaster of fluctuating diesel prices, a key variable to operating costs. Today, with diesel prices remaining persistently high, trucking companies are faced with a stark challenge: balancing razor-thin profit margins while maintaining operational reliability. To survive and thrive, many have turned to innovative fuel-saving technologies to optimize costs and enhance efficiency.

This shift is driven not merely by economic necessity but also by evolving government mandates, consumer pressure for greener supply chains, and the desire to remain competitive in a rapidly advancing transportation ecosystem. The adoption of fuel-efficient solutions such as aerodynamic enhancements and hybrid powertrains reflects both the constraints and opportunities the industry faces in the 21st century. Let’s explore the dynamics behind this trend, the technologies paving the way, and the broader implications for the industry.

**The Financial Pressure of High Diesel Prices**

The diesel spike over the past few years has placed immense financial stress on trucking companies. Fuel typically accounts for roughly 20-25% of a fleet’s total operating costs, a percentage that balloons during periods of price surges. For companies that operate hundreds or thousands of trucks, small changes in fuel prices can cascade into millions of dollars in added expenses.

Small and medium-sized fleets feel the pinch the most. These companies often lack the profit margins or economies of scale to offset surging fuel costs, leaving them particularly vulnerable to market volatility. Moreover, when diesel costs climb, it becomes harder for carriers to maintain affordable pricing for their customers, potentially jeopardizing transport contracts and long-term client relationships. The strain has compelled fleets, both large and small, to reevaluate how they operate and identify technologies that promise immediate and long-term savings.

**Aerodynamic Enhancements: The Low-Hanging Fruit of Fuel Efficiency**

The trucking industry has long understood that reducing aerodynamic drag is one of the most cost-effective ways to improve fuel efficiency. Advancements in aerodynamics, particularly in tractor-trailer designs, are now taking center stage as a practical solution to mitigate rising fuel expenses. By refining truck shapes, introducing specialized attachments, and leveraging advanced materials, trucks can cut drag significantly, directly translating into lower fuel consumption.

Devices like side skirts, wheel covers, and gap reducers help air move more fluidly around and beneath the vehicle, reducing pockets of turbulence that increase resistance. Meanwhile, innovations like trailer tails and roof fairings allow for better airflow around the back and top of the truck, areas traditionally prone to drag. Fleet operators adopting these systems are seeing fuel savings ranging from 4-10%, depending on the configuration and routes driven. For a company operating hundreds of trucks, even small percentage savings can add up to millions of dollars annually.

However, the return on investment for aerodynamic modifications depends on several factors, including the type of routes driven. Trucks operating primarily on highways and long-distance runs see the greatest benefit, as high speeds accentuate the impact of drag reduction. Companies focused on urban or regional hauls may not achieve the same savings due to their stop-and-go driving patterns, but the technology is rapidly evolving to address broader use cases.

**Hybrid Powertrains: The Next Frontier in Sustainable Trucking**

Although hybrids are more frequently associated with passenger cars, hybrid powertrains are emerging as a game-changer in the trucking industry. These systems leverage the combination of an internal combustion engine and an electric motor to reduce fuel dependence and improve overall efficiency. While the upfront cost of hybrid trucks often exceeds that of their diesel-only counterparts, the long-term fuel savings and potentially reduced maintenance costs are enticing fleet managers to consider the switch.

Hybrid technology particularly shines in urban and regional deliveries where frequent stops—traditionally an Achilles’ heel for diesel efficiency—become an opportunity for energy regeneration. Advanced systems capture and store energy during braking or coasting, using it to power the electric motor during acceleration. This technology reduces the amount of diesel consumed, especially in stop-heavy environments or when hauling moderate loads.

Several leading trucking manufacturers are already introducing hybrid Class 8 and medium-duty trucks. Companies that utilize these hybrid fleets are reporting fuel savings of around 20-30%, a figure that becomes more lucrative as diesel prices show no sign of substantial decline. Combined with government incentives for adopting greener technology, hybridization offers an attractive path toward fuel savings and sustainability.

Despite their promise, hybrid powertrains still face challenges. Limited availability, higher upfront costs, and concerns over maintenance complexity remain barriers to widespread adoption. However, as technology progresses and economies of scale bring down prices, hybrid trucks are likely to account for an increasingly significant share of new vehicle purchases.

**The Push Toward Fully Electric Trucks and Long-Term Implications**

Though still in its infancy, the development of electric semi-trucks illustrates the industry’s broader ambition to move beyond diesel altogether. Electric trucks, like those introduced by Tesla and other automakers, represent the ultimate vision of low-carbon, cost-efficient freight transportation. Fully electric trucks promise complete independence from diesel prices, eliminating the volatility that has long haunted the trucking sector.

However, full electrification faces its own hurdles, particularly in terms of range, charging infrastructure, and battery technology. Current electric trucks are mostly limited to urban or short-haul applications, as their range cannot yet compete with diesel. Efforts are underway to build high-capacity charging networks, but this long-term infrastructure investment is still years away from being widely accessible.

In the meantime, hybrid powertrains act as a bridge between diesel vehicles and fully electric fleets, offering an intermediate solution that addresses both economic and environmental concerns. The increasing adoption of hybrids also demonstrates a growing willingness in the trucking industry to embrace incremental innovation, viewing efficiency gains as a journey rather than an immediate destination.

**Beyond Technological Innovation: Policy and Collaboration**

Technology alone cannot solve the challenges posed by high diesel prices and fuel consumption. Public policy and industry collaboration play equally critical roles in shaping the future of trucking. Some state governments are already incentivizing the adoption of fuel-efficient technologies through tax breaks and grants. California, for example, has instituted regulations requiring improved fuel efficiency and lower greenhouse gas emissions from trucks operating within the state.

Private-sector partnerships are also proving effective, with trucking companies collaborating with technology firms, research institutions, and logistics providers to innovate and refine efficiency solutions. Industry-wide adoption of standardized fuel-saving best practices can drive additional savings and create a more sustainable ecosystem, amplifying the benefits of individual company decisions.

**The Bottom Line: Navigating a Transforming Industry**

Trucking companies today face a dual challenge. They must remain operationally efficient amid high diesel prices while adapting to the increasing demand for greener and more sustainable supply chains. Turning to fuel-saving technologies like aerodynamics and hybrid powertrains has emerged as a viable strategy for achieving both objectives, demonstrating the industry’s resilience and ability to innovate in the face of adversity.

As the industry continues to invest in these advancements, the benefits extend beyond just fuel savings or emissions reductions. Enhanced efficiency strengthens the bottom line, promotes sustainability efforts, and can even improve driver retention by offering better-designed, lower-emissions vehicles. With diesel prices unlikely to stabilize significantly soon and environmental regulations tightening, the adoption of fuel-saving technologies is not only an opportunity but an imperative for the trucking industry.

In the coming years, we’re likely to see even greater convergence of innovation, policy, and market forces shaping the trajectory of fuel efficiency in trucking. Companies willing to invest in these technologies today are positioning themselves not just to weather current challenges but to lead the evolving future of freight transportation.

Diesel is the lifeblood of the trucking industry, propelling millions of trucks each year across the highways that power the US supply chain. Yet for decades, the industry has ridden the rollercoaster of fluctuating diesel prices, a key variable to operating costs. Today, with diesel prices remaining persistently high, trucking companies are faced with a stark challenge: balancing razor-thin profit margins while maintaining operational reliability. To survive and thrive, many have turned to innovative fuel-saving technologies to optimize costs and enhance efficiency.

This shift is driven not merely by economic necessity but also by evolving government mandates, consumer pressure for greener supply chains, and the desire to remain competitive in a rapidly advancing transportation ecosystem. The adoption of fuel-efficient solutions such as aerodynamic enhancements and hybrid powertrains reflects both the constraints and opportunities the industry faces in the 21st century. Let’s explore the dynamics behind this trend, the technologies paving the way, and the broader implications for the industry.

**The Financial Pressure of High Diesel Prices**

The diesel spike over the past few years has placed immense financial stress on trucking companies. Fuel typically accounts for roughly 20-25% of a fleet’s total operating costs, a percentage that balloons during periods of price surges. For companies that operate hundreds or thousands of trucks, small changes in fuel prices can cascade into millions of dollars in added expenses.

Small and medium-sized fleets feel the pinch the most. These companies often lack the profit margins or economies of scale to offset surging fuel costs, leaving them particularly vulnerable to market volatility. Moreover, when diesel costs climb, it becomes harder for carriers to maintain affordable pricing for their customers, potentially jeopardizing transport contracts and long-term client relationships. The strain has compelled fleets, both large and small, to reevaluate how they operate and identify technologies that promise immediate and long-term savings.

**Aerodynamic Enhancements: The Low-Hanging Fruit of Fuel Efficiency**

The trucking industry has long understood that reducing aerodynamic drag is one of the most cost-effective ways to improve fuel efficiency. Advancements in aerodynamics, particularly in tractor-trailer designs, are now taking center stage as a practical solution to mitigate rising fuel expenses. By refining truck shapes, introducing specialized attachments, and leveraging advanced materials, trucks can cut drag significantly, directly translating into lower fuel consumption.

Devices like side skirts, wheel covers, and gap reducers help air move more fluidly around and beneath the vehicle, reducing pockets of turbulence that increase resistance. Meanwhile, innovations like trailer tails and roof fairings allow for better airflow around the back and top of the truck, areas traditionally prone to drag. Fleet operators adopting these systems are seeing fuel savings ranging from 4-10%, depending on the configuration and routes driven. For a company operating hundreds of trucks, even small percentage savings can add up to millions of dollars annually.

However, the return on investment for aerodynamic modifications depends on several factors, including the type of routes driven. Trucks operating primarily on highways and long-distance runs see the greatest benefit, as high speeds accentuate the impact of drag reduction. Companies focused on urban or regional hauls may not achieve the same savings due to their stop-and-go driving patterns, but the technology is rapidly evolving to address broader use cases.

**Hybrid Powertrains: The Next Frontier in Sustainable Trucking**

Although hybrids are more frequently associated with passenger cars, hybrid powertrains are emerging as a game-changer in the trucking industry. These systems leverage the combination of an internal combustion engine and an electric motor to reduce fuel dependence and improve overall efficiency. While the upfront cost of hybrid trucks often exceeds that of their diesel-only counterparts, the long-term fuel savings and potentially reduced maintenance costs are enticing fleet managers to consider the switch.

Hybrid technology particularly shines in urban and regional deliveries where frequent stops—traditionally an Achilles’ heel for diesel efficiency—become an opportunity for energy regeneration. Advanced systems capture and store energy during braking or coasting, using it to power the electric motor during acceleration. This technology reduces the amount of diesel consumed, especially in stop-heavy environments or when hauling moderate loads.

Several leading trucking manufacturers are already introducing hybrid Class 8 and medium-duty trucks. Companies that utilize these hybrid fleets are reporting fuel savings of around 20-30%, a figure that becomes more lucrative as diesel prices show no sign of substantial decline. Combined with government incentives for adopting greener technology, hybridization offers an attractive path toward fuel savings and sustainability.

Despite their promise, hybrid powertrains still face challenges. Limited availability, higher upfront costs, and concerns over maintenance complexity remain barriers to widespread adoption. However, as technology progresses and economies of scale bring down prices, hybrid trucks are likely to account for an increasingly significant share of new vehicle purchases.

**The Push Toward Fully Electric Trucks and Long-Term Implications**

Though still in its infancy, the development of electric semi-trucks illustrates the industry’s broader ambition to move beyond diesel altogether. Electric trucks, like those introduced by Tesla and other automakers, represent the ultimate vision of low-carbon, cost-efficient freight transportation. Fully electric trucks promise complete independence from diesel prices, eliminating the volatility that has long haunted the trucking sector.

However, full electrification faces its own hurdles, particularly in terms of range, charging infrastructure, and battery technology. Current electric trucks are mostly limited to urban or short-haul applications, as their range cannot yet compete with diesel. Efforts are underway to build high-capacity charging networks, but this long-term infrastructure investment is still years away from being widely accessible.

In the meantime, hybrid powertrains act as a bridge between diesel vehicles and fully electric fleets, offering an intermediate solution that addresses both economic and environmental concerns. The increasing adoption of hybrids also demonstrates a growing willingness in the trucking industry to embrace incremental innovation, viewing efficiency gains as a journey rather than an immediate destination.

**Beyond Technological Innovation: Policy and Collaboration**

Technology alone cannot solve the challenges posed by high diesel prices and fuel consumption. Public policy and industry collaboration play equally critical roles in shaping the future of trucking. Some state governments are already incentivizing the adoption of fuel-efficient technologies through tax breaks and grants. California, for example, has instituted regulations requiring improved fuel efficiency and lower greenhouse gas emissions from trucks operating within the state.

Private-sector partnerships are also proving effective, with trucking companies collaborating with technology firms, research institutions, and logistics providers to innovate and refine efficiency solutions. Industry-wide adoption of standardized fuel-saving best practices can drive additional savings and create a more sustainable ecosystem, amplifying the benefits of individual company decisions.

**The Bottom Line: Navigating a Transforming Industry**

Trucking companies today face a dual challenge. They must remain operationally efficient amid high diesel prices while adapting to the increasing demand for greener and more sustainable supply chains. Turning to fuel-saving technologies like aerodynamics and hybrid powertrains has emerged as a viable strategy for achieving both objectives, demonstrating the industry’s resilience and ability to innovate in the face of adversity.

As the industry continues to invest in these advancements, the benefits extend beyond just fuel savings or emissions reductions. Enhanced efficiency strengthens the bottom line, promotes sustainability efforts, and can even improve driver retention by offering better-designed, lower-emissions vehicles. With diesel prices unlikely to stabilize significantly soon and environmental regulations tightening, the adoption of fuel-saving technologies is not only an opportunity but an imperative for the trucking industry.

In the coming years, we’re likely to see even greater convergence of innovation, policy, and market forces shaping the trajectory of fuel efficiency in trucking. Companies willing to invest in these technologies today are positioning themselves not just to weather current challenges but to lead the evolving future of freight transportation.

With diesel prices pushing profitability into tight margins, trucking companies in the US are leveraging cutting-edge fuel-saving technologies like aerodynamics and hybrid powertrains. Discover how these advancements are transforming the future of freight transportation.

Diesel is the lifeblood of the trucking industry, propelling millions of trucks each year across the highways that power the US supply chain. Yet for decades, the industry has ridden the rollercoaster of fluctuating diesel prices, a key variable to operating costs. Today, with diesel prices remaining persistently high, trucking companies are faced with a stark challenge: balancing razor-thin profit margins while maintaining operational reliability. To survive and thrive, many have turned to innovative fuel-saving technologies to optimize costs and enhance efficiency.

This shift is driven not merely by economic necessity but also by evolving government mandates, consumer pressure for greener supply chains, and the desire to remain competitive in a rapidly advancing transportation ecosystem. The adoption of fuel-efficient solutions such as aerodynamic enhancements and hybrid powertrains reflects both the constraints and opportunities the industry faces in the 21st century. Let’s explore the dynamics behind this trend, the technologies paving the way, and the broader implications for the industry.

**The Financial Pressure of High Diesel Prices**

The diesel spike over the past few years has placed immense financial stress on trucking companies. Fuel typically accounts for roughly 20-25% of a fleet’s total operating costs, a percentage that balloons during periods of price surges. For companies that operate hundreds or thousands of trucks, small changes in fuel prices can cascade into millions of dollars in added expenses.

Small and medium-sized fleets feel the pinch the most. These companies often lack the profit margins or economies of scale to offset surging fuel costs, leaving them particularly vulnerable to market volatility. Moreover, when diesel costs climb, it becomes harder for carriers to maintain affordable pricing for their customers, potentially jeopardizing transport contracts and long-term client relationships. The strain has compelled fleets, both large and small, to reevaluate how they operate and identify technologies that promise immediate and long-term savings.

**Aerodynamic Enhancements: The Low-Hanging Fruit of Fuel Efficiency**

The trucking industry has long understood that reducing aerodynamic drag is one of the most cost-effective ways to improve fuel efficiency. Advancements in aerodynamics, particularly in tractor-trailer designs, are now taking center stage as a practical solution to mitigate rising fuel expenses. By refining truck shapes, introducing specialized attachments, and leveraging advanced materials, trucks can cut drag significantly, directly translating into lower fuel consumption.

Devices like side skirts, wheel covers, and gap reducers help air move more fluidly around and beneath the vehicle, reducing pockets of turbulence that increase resistance. Meanwhile, innovations like trailer tails and roof fairings allow for better airflow around the back and top of the truck, areas traditionally prone to drag. Fleet operators adopting these systems are seeing fuel savings ranging from 4-10%, depending on the configuration and routes driven. For a company operating hundreds of trucks, even small percentage savings can add up to millions of dollars annually.

However, the return on investment for aerodynamic modifications depends on several factors, including the type of routes driven. Trucks operating primarily on highways and long-distance runs see the greatest benefit, as high speeds accentuate the impact of drag reduction. Companies focused on urban or regional hauls may not achieve the same savings due to their stop-and-go driving patterns, but the technology is rapidly evolving to address broader use cases.

**Hybrid Powertrains: The Next Frontier in Sustainable Trucking**

Although hybrids are more frequently associated with passenger cars, hybrid powertrains are emerging as a game-changer in the trucking industry. These systems leverage the combination of an internal combustion engine and an electric motor to reduce fuel dependence and improve overall efficiency. While the upfront cost of hybrid trucks often exceeds that of their diesel-only counterparts, the long-term fuel savings and potentially reduced maintenance costs are enticing fleet managers to consider the switch.

Hybrid technology particularly shines in urban and regional deliveries where frequent stops—traditionally an Achilles’ heel for diesel efficiency—become an opportunity for energy regeneration. Advanced systems capture and store energy during braking or coasting, using it to power the electric motor during acceleration. This technology reduces the amount of diesel consumed, especially in stop-heavy environments or when hauling moderate loads.

Several leading trucking manufacturers are already introducing hybrid Class 8 and medium-duty trucks. Companies that utilize these hybrid fleets are reporting fuel savings of around 20-30%, a figure that becomes more lucrative as diesel prices show no sign of substantial decline. Combined with government incentives for adopting greener technology, hybridization offers an attractive path toward fuel savings and sustainability.

Despite their promise, hybrid powertrains still face challenges. Limited availability, higher upfront costs, and concerns over maintenance complexity remain barriers to widespread adoption. However, as technology progresses and economies of scale bring down prices, hybrid trucks are likely to account for an increasingly significant share of new vehicle purchases.

**The Push Toward Fully Electric Trucks and Long-Term Implications**

Though still in its infancy, the development of electric semi-trucks illustrates the industry’s broader ambition to move beyond diesel altogether. Electric trucks, like those introduced by Tesla and other automakers, represent the ultimate vision of low-carbon, cost-efficient freight transportation. Fully electric trucks promise complete independence from diesel prices, eliminating the volatility that has long haunted the trucking sector.

However, full electrification faces its own hurdles, particularly in terms of range, charging infrastructure, and battery technology. Current electric trucks are mostly limited to urban or short-haul applications, as their range cannot yet compete with diesel. Efforts are underway to build high-capacity charging networks, but this long-term infrastructure investment is still years away from being widely accessible.

In the meantime, hybrid powertrains act as a bridge between diesel vehicles and fully electric fleets, offering an intermediate solution that addresses both economic and environmental concerns. The increasing adoption of hybrids also demonstrates a growing willingness in the trucking industry to embrace incremental innovation, viewing efficiency gains as a journey rather than an immediate destination.

**Beyond Technological Innovation: Policy and Collaboration**

Technology alone cannot solve the challenges posed by high diesel prices and fuel consumption. Public policy and industry collaboration play equally critical roles in shaping the future of trucking. Some state governments are already incentivizing the adoption of fuel-efficient technologies through tax breaks and grants. California, for example, has instituted regulations requiring improved fuel efficiency and lower greenhouse gas emissions from trucks operating within the state.

Private-sector partnerships are also proving effective, with trucking companies collaborating with technology firms, research institutions, and logistics providers to innovate and refine efficiency solutions. Industry-wide adoption of standardized fuel-saving best practices can drive additional savings and create a more sustainable ecosystem, amplifying the benefits of individual company decisions.

**The Bottom Line: Navigating a Transforming Industry**

Trucking companies today face a dual challenge. They must remain operationally efficient amid high diesel prices while adapting to the increasing demand for greener and more sustainable supply chains. Turning to fuel-saving technologies like aerodynamics and hybrid powertrains has emerged as a viable strategy for achieving both objectives, demonstrating the industry’s resilience and ability to innovate in the face of adversity.

As the industry continues to invest in these advancements, the benefits extend beyond just fuel savings or emissions reductions. Enhanced efficiency strengthens the bottom line, promotes sustainability efforts, and can even improve driver retention by offering better-designed, lower-emissions vehicles. With diesel prices unlikely to stabilize significantly soon and environmental regulations tightening, the adoption of fuel-saving technologies is not only an opportunity but an imperative for the trucking industry.

In the coming years, we’re likely to see even greater convergence of innovation, policy, and market forces shaping the trajectory of fuel efficiency in trucking. Companies willing to invest in these technologies today are positioning themselves not just to weather current challenges but to lead the evolving future of freight transportation.

Other Blogs

Other Blogs

Check our other project Blogs with useful insight and information for your businesses

Other Blogs

Other Blogs

Check our other project Blogs with useful insight and information for your businesses

Other Blogs

Other Blogs

Check our other project Blogs with useful insight and information for your businesses